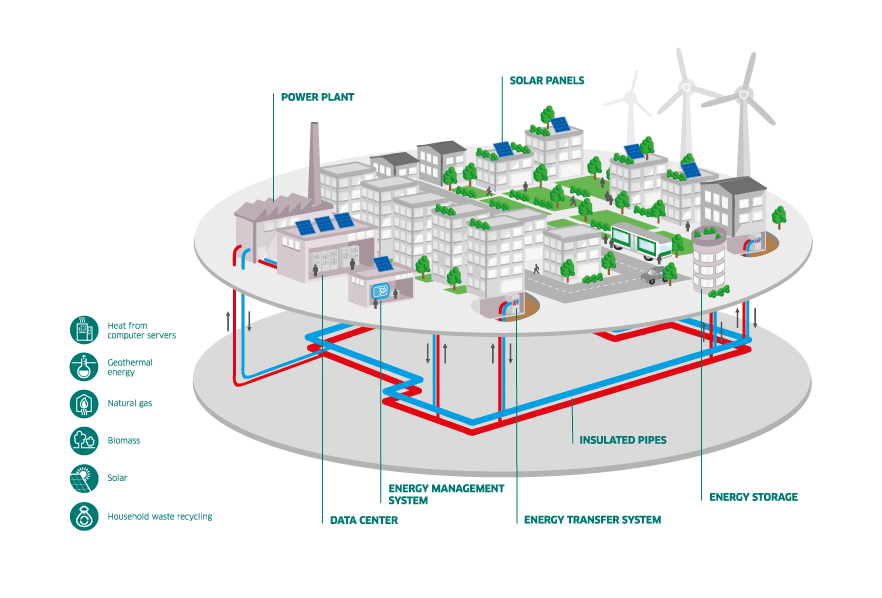

District Heating Services

Installing District Heating Systems

Commercial Heating and Plumbing

OLBY Mechanical can deliver all your commercial District Heating requirements using our wealth of experience in installing these systems for many years. We have key partners who can deliver on the Civil Engineering works required to allow for the installation of your District Heating mains. We have experience in using various suppliers of Pre-Insulated Pipework to include: Power Pipe, CPV, Star and Log Store, just to name but a few.

We have experience in working on single pipe steel mains, fully welded to a ISO 9606-1 standard, single pipe and dual-pipe plastics using thermal welding techniques. All OLBY Mechanical operatives are fully conversant with each system and fully trained by each supplier in the encapsulation works required upon successful completion of the jointing and the leak detection systems.

OLBY Mechanical have worked on District Heating systems in and around the Midlands, North East, London and the South coast for a variety of clients to include, Local Councils, Colleges & Universities, Housing Developers and Government Procurers.

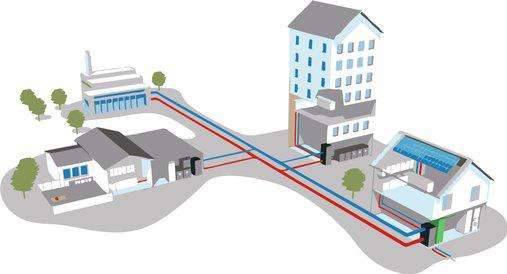

Repairs to District Heating Systems Mains

OLBY Mechanical can carry out any repairs required to your District Heating Mains or encapsulated pipework whether steel or PE pipe. This will include the repair of leaks to existing welds, fractured mains or corroded pipework on all types of system.

OLBY Mechanical can also repair the insulation, leak detection system and the protective casing of the encapsulated pipework using approved and trained methods.

OLBY Mechanical operatives have all been trained to work on encapsulated pipework and the sealing of the outer casing by various manufacturers of encapsulated pipe to include the likes of CPV, LOG STORE and POWER PIPE systems.

Live Connections

OLBY Mechanical can successfully carry out additional connections to existing systems without the need to disrupt the system or services in use. By welding a branch connection onto the main itself, we can then attach a new full-bore valve and then attach our pressurised tapping rig and drill into the existing live main, creating a new branch connection and isolation point. This will allow the existing supply to be unaffected by the additional works required and thus saving on costly disconnection of services and drain downs.