What is Oxy-Acetylene welding?

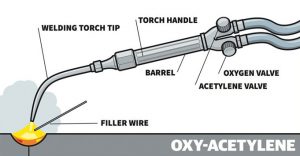

Our specialist team of engineers use a variety of techniques when welding or connecting pipework. Oxyacetylene is one such form and is a type of welding and cutting technique that uses a very hot flame that is produced by mixing acetylene and oxygen.

French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903.

The flame on Oxy-acetylene works well when melting high and low-temperature metals. It is a piece of portable welding equipment that is more portable than other welding equipment and can be used to flame-cut larger pieces of metal.

What are the benefits of pipe insulation?

OLBY has a fully equipped workshop and can deliver manufactured pipework anywhere in the UK and Europe.

Pipe Insulation ensures that any pipework that is touched remains at a safe temperature, it also provides significant energy savings by reducing the loss of heat or cold over longer distances. This is known as thermal resistance.

Pipe insulation is also known as pipe lagging and is suitable for both copper and plastic hot and cold pipes.